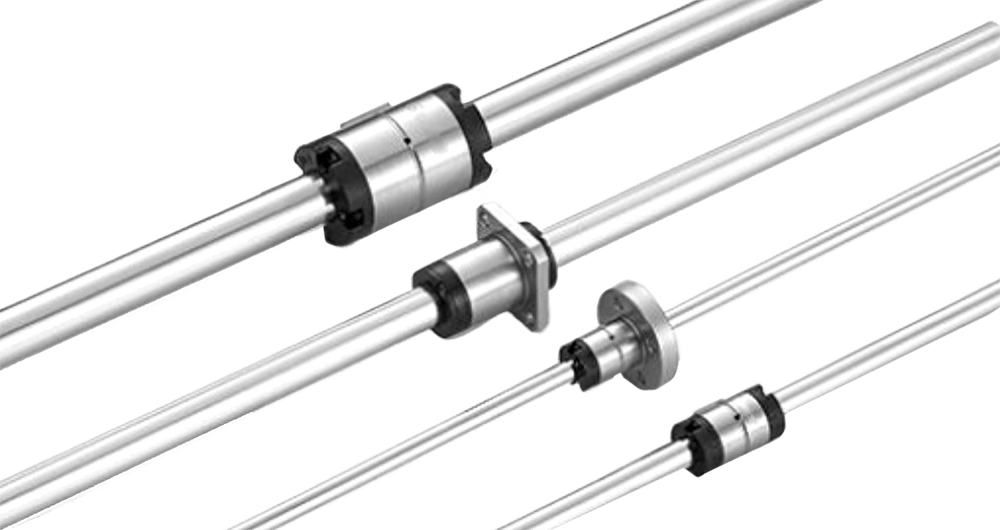

Ball spline structure

Products are widely used in sewing equipment, textile, engraving, cutting automation and other manufacturing industries. Since the launch of the second generation of ultra-high quality guide rails developed by the company, they have been widely used in aerospace, automotive, military and other fields, and are deeply welcomed by customers!

Ball spline

Ball spline

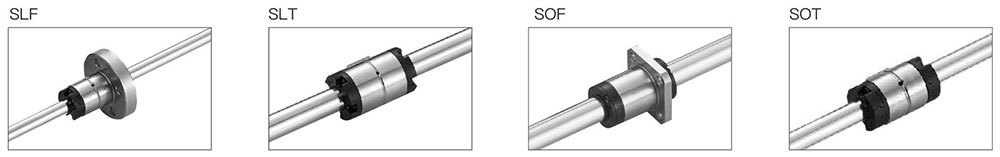

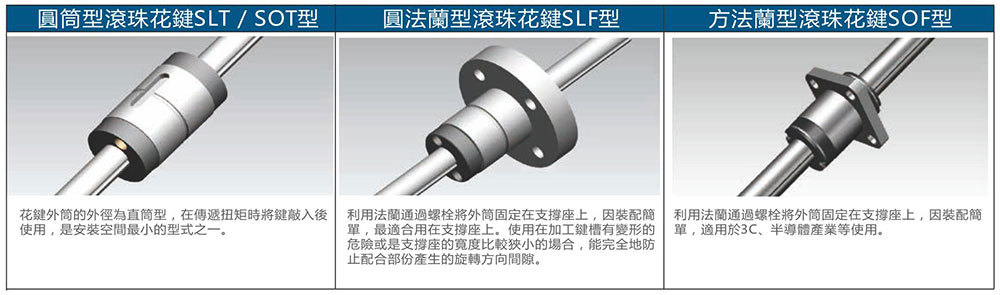

Ball splines can be divided into four types: round flange SLF type, cylindrical SLT type, method flange SOF type, and cylindrical SOT type.

Category:

Detailed description

Ball splines utilize balls housed within the spline shaft outer cylinder, smoothly rolling and transmitting torque within precisely ground rolling grooves. Employing a unique contact point design with a larger contact angle (40°), they offer high sensitivity and significantly improved load capacity. They are suitable for environments with excessive vibration and impact loads, high positioning accuracy requirements, and high-speed motion needs, effectively functioning under such conditions. Even when replacing linear ball bushings, with the same shaft diameter, the rated load of a ball spline is ten times greater, allowing for compact designs and safe, durable operation under cantilever loads and torque.

Ball splines are available in four types: round flange SLF type, cylindrical SLT type, square flange SOF type, and cylindrical SOT type. Depending on the shaft diameter and ball contact path, they are available in 2 rows (180°) (SLF/SLT6~20), (SOT/SOF8~25) and 4 rows (70°) (SLF/SLT25~50). Hollow shafts are also available.

Advantages of Ball Splines

High Load Capacity

The ball rolling grooves are precisely ground and utilize a 40° gothic arch contact angle. Due to the large contact angle, it has a high load capacity in both radial and torque directions.

Zero Backlash in Rotation

By using a relative 2-4 rows of balls with a 40° contact angle, the spline shaft and spline outer cylinder are combined, and the backlash in the rotational direction can be zeroed through preload adjustment.

High Sensitivity

Due to the special design of the ball contact point, in addition to high rigidity, it also has high sensitivity and reduces energy waste.

High Rigidity

Due to the large contact angle, it has high rigidity, and appropriate preload can be applied according to the situation, so higher torsional rigidity and moment rigidity can be obtained.

Easy Assembly

Due to the special design, even if the spline outer cylinder is separated from the spline shaft, the balls will not fall off. Therefore, assembly, maintenance, and inspection are easy to perform.

Types and Features of Ball Splines

Spline Outer Cylinder Types

Spline Shaft Types

SL Series Product Specifications

Nominal Designation

The SL series is divided into ready-to-assemble and single-output types. Both have the same dimensions. The main difference is that the ready-to-assemble type is cut and assembled by the factory according to customer orders, achieving precision-grade assembly accuracy. The single-output type's spline shaft and outer cylinder can be shipped separately, offering greater convenience, but the combined accuracy cannot reach the precision grade. However, strict quality control is maintained in the manufacturing process, so the accuracy of the single-output type has reached a world-class level and is easy to assemble. Customers can prepare and assemble parts themselves, which is very convenient.

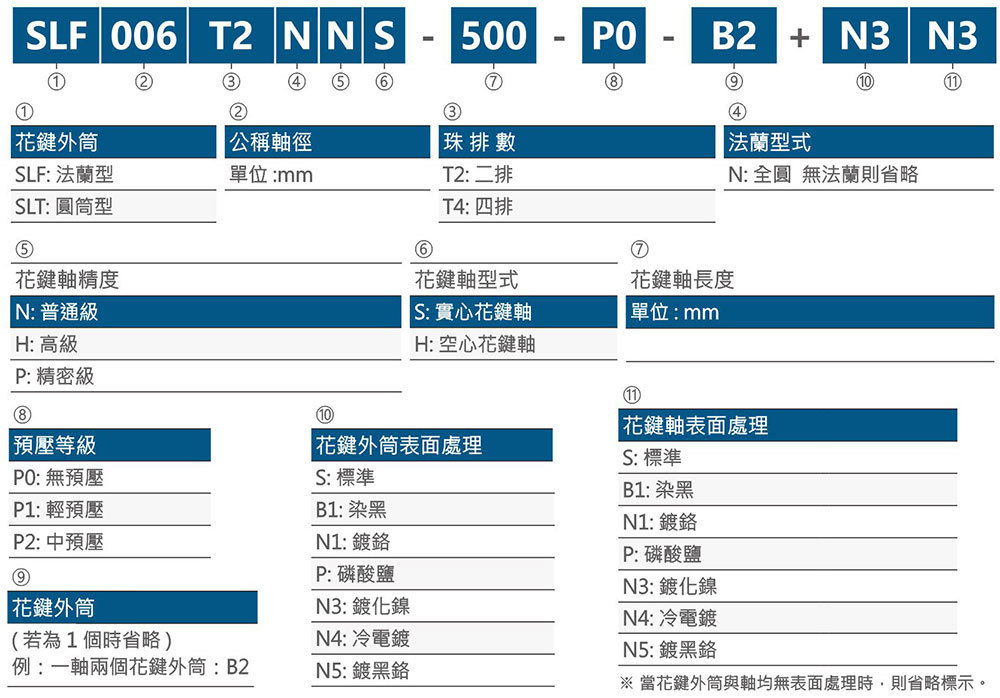

Ready-to-Assemble Ball Spline Set Model Numbers

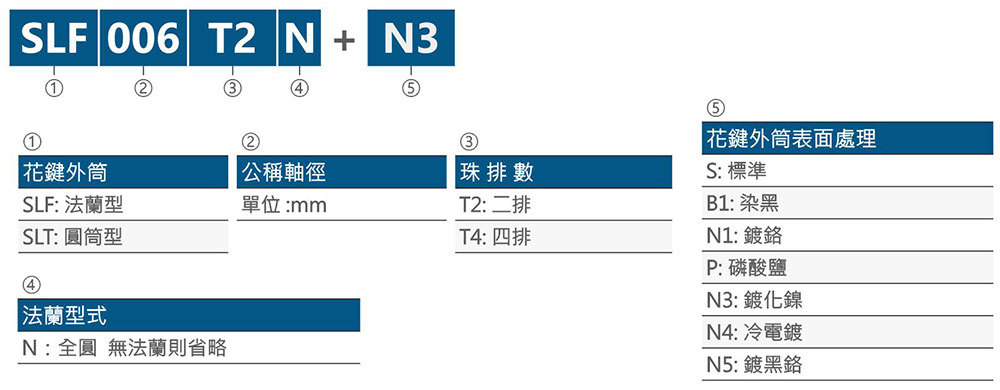

Single-Output Spline Outer Cylinder Model Numbers

Keywords:

spline

cylinder

splines

accuracy

square

linear

Related Products